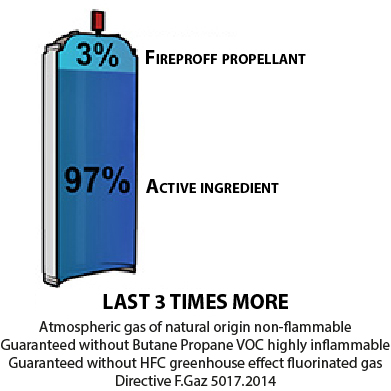

ANTI-SPATTER NON-FLAMMABLE

SPRAY FOR NOZZLES

ANTI-SPATTER SCRATCH WELDING SPRAY FOR SHEET METAL AND STRUCTURES

SUITABLE FOR ALL WELDING METHODS

AND FOR ALL WIRE DIAMETERS, INCLUDING AUTOMATIC WELDING

DOES NOT PRODUCE SPLITS,

OR ALLOW DEFECTS OR THE APPEARANCE OF DEFECTS

DESCRIPTION

Prevents spatters adhesion and protects nozzles and welded parts.

Is appropriate for all wire diameters, even at high intensity.

Does not stain, odorless. Does not oxidize metallic parts.

Free from silicon, metallic particles and graphite.

Compared to the products on the market, it has a long-term effectiveness, which allows less frequent treatments on nozzle.

This anti-spatter agent is usable on vertical or horizontal surfaces, and is suitable for all methods of braze welding, welding, arc welding, even in automatic, with consumable electrode (MIG and MAG), under CO2, argon, ATAL or mixtures. It does not generate cracking.

It can be easily removed with solvents, after application on metallic sheets or parts.

It ensures an anti-corrosive and antioxidant protection of the parts.

APPLICATIONS

Protection of metallic sheets, on all natures, against the projection of chips and corrosion.

Protection of nozzles of all intensities and all diameters of wire.

Mechanical engineering.

Electro-welded material.

Electric motors.

Shipbuilding.

Railway construction.

Automotive engineering.

Manufacture of welded rolled nozzles.

Manufacture of machines.

PHYSICO-CHEMICAL PROPERTIES TYPICALS

|

PROPERTIE |

STANDARD or PRACTICE |

VALUE |

MEASUREMENT (UNIT) |

|

Appearance |

Visual |

Liquid |

- |

|

Colour Saybolt |

NF M 07.003 ASTM D 156 |

+30 |

Rating |

|

Odour |

Olfactory sense |

slight, characteristic |

- |

|

Density at 20°C |

ISO 12.155 |

1290 |

g/L |

|

Surface tension at 20°C |

ISO 6297 |

30.3 |

Dynes/cm |

|

PROPERTIES OF ACTIVE INGREDIENTS |

|||

|

PROPERTIE |

STANDARD OR PRACTICE |

VALUE |

MEASUREMENT (UNIT) |

|

Kinematic viscosity at 40°C |

NF EN 3104 |

415 |

mm2/sec |

|

Auto-ignition point |

ASTM E 659 |

Non-flammable |

°C |

|

Acid value |

ISO 6618 |

<0.1 |

mg/(KOH)/L |

|

Sulphated ash content |

NFT 60 144 |

0.0 |

% |

|

Impurity content greater than 5µ |

FTMS 791 3005 |

0 |

nb/ml |

|

Refractive index |

ISO 5661 |

1.4260 |

- |

INSTRUCTIONS FOR USE

Shake the spray a few moments from the bottom up.

Spray in approximately 15 cm surfaces to be protected against the projections of let us scratch.

Apply on cold nozzles. Apply on metallic sheets or parts, without excess.

Let evaporate solvents a few moments before carrying out welding.

Be sure there is no residual trace of AS 50 before post-welding treatments. In this case eliminate before any later surface treatment, with an organic solvent.

Usable spray in all positions.

PRESENTATION

|

|

Aerosol 650 ml

|

Looking for another product ?

Discover our entire range by clicking on the photo

Manufacturing, lubrification, cleansing, protection,

IBiotec® Tec Industries® Service

offers a wide range of products reserved for industrial area

If you wish for :

a free sample

a technical advice

a product data sheet

a safety data sheet

IBiotec® Tec Industries®Service

manufacturer of technical chemical products.

Welcome to our website.